When an aerial lift is damaged or cannot be operated, it may need to be moved for maintenance repairs and general safety. Owners and operators should use extreme caution when disabling and moving a down unit as the machine can move freely and potentially result in serious injury or worse.

Before beginning, make sure the unit is on a flat surface or is supported by a capable vehicle. Releasing the hub will allow the unit to roll freely without the ability to apply the brakes. Proceed with caution as the above process is performed on all four wheel hubs.

BOOM LIFTS

There are a few options for freewheeling a disabled boom lift. Please refer to the unit’s operator’s manual for exact steps required.

Before moving a disabled unit, ensure the boom is in a safe position.

Disengaging a boom lift drive

On most units that have torque hubs, there are two small bolts holding the disengagement plate in place. Locate the bolts in the center of the face of the hub to remove each one. Turn the disconnect plate over using the nipple to push the disengage rod into the body of the gear hub. This will release the sun gear from the planetary gears and freewheel the hub.

On the Snorkel A38E, there is one hex bolt in the center that needs to be threaded all the way in to release the brakes.

Warning! When the hubs are disengaged, there are NO BRAKES holding the aerial lift. The aerial lift may move uncontrollably when the drive hubs are disengaged. Only disengage while on flat, level ground and/or with the machine properly chocked or restrained. Death or serious injury could result. Re-engage the drive hubs before operating the aerial platform.

Start by towing the boom lift to a desired location. Once the unit is secured, reverse the steps above to re-engage the drive hubs. Pull the disconnect cap from each hub and turn it over where the nipple faces outward. Be cautious when the cap has been removed as the disengage rod is under spring tension and can come out of the hub under pressure.

SCISSOR LIFTS

There are several options for releasing the brakes on a scissor lift. Please refer to the unit’s operator’s manual for the exact steps required.

Before moving a disabled unit ensure the scissor stack is in a safe position.

Disabling a scissor lift

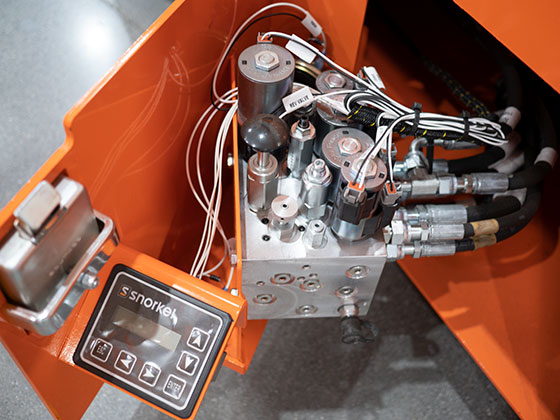

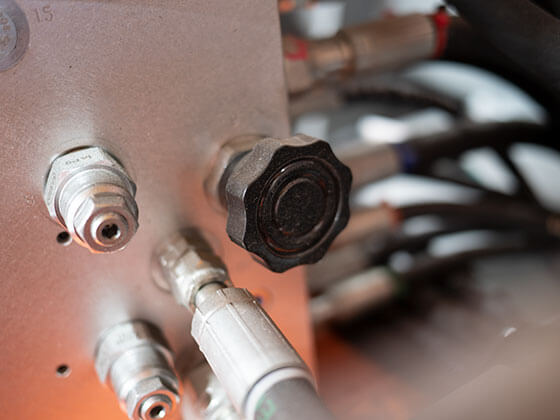

The brake release valve and freewheeling valve are located on the main hydraulic manifold. The brake release pump, located on the valve, will allow pressure to be generated in order to release the spring-applied, hydraulic-released brake packs. The freewheeling valve allows for the hydraulic oil in the drive system to free flow between the motors for the wheels in order to roll with little to no resistance.

Warning! The aerial platform is free to move when the brakes and freewheeling valve are disabled. Death or serious injury could result. Only disengage while on flat, level ground and/or with the machine properly chocked or restrained. Close the freewheeling valve and reset the brakes before operating the aerial platform.

Before beginning, make sure the unit is on a flat surface or is supported by a capable vehicle. Release the brakes, open the freewheeling valve, then push, pull or tow the unit to desired location.

Parking the scissor lift

Once the unit is in the desired location, release the pressure on the brake system to set the parking brake. Reference the operator’s manual for the entire brake pressure release procedure.